What is the difference between plastic-lined centrifugal pump and all-plastic centrifugal pump?

What is the difference between plastic-lined centrifugal pump and all-plastic centrifugal pump?

Plastic lined centrifugal pump and all-plastic centrifugal pump we have heard the most should be lined pump, mainly for the chemical pump flow parts and channel metal nesting, in the surface plating polytetrafluoroethylene plastic, to prevent the chemical pump due to the corrosion of the medium and damage the smoothness of the flow channel, while affecting the efficiency of the chemical pump, change the nature of the medium, The whole plastic pump is the whole pump head is made of polytetrafluoroethylene plastic casting, the plastics used in these two kinds of pumps are polytetrafluoroethylene material, which can effectively transport some acid alkaline, organic solvents, oxidants and other chemical solvents.

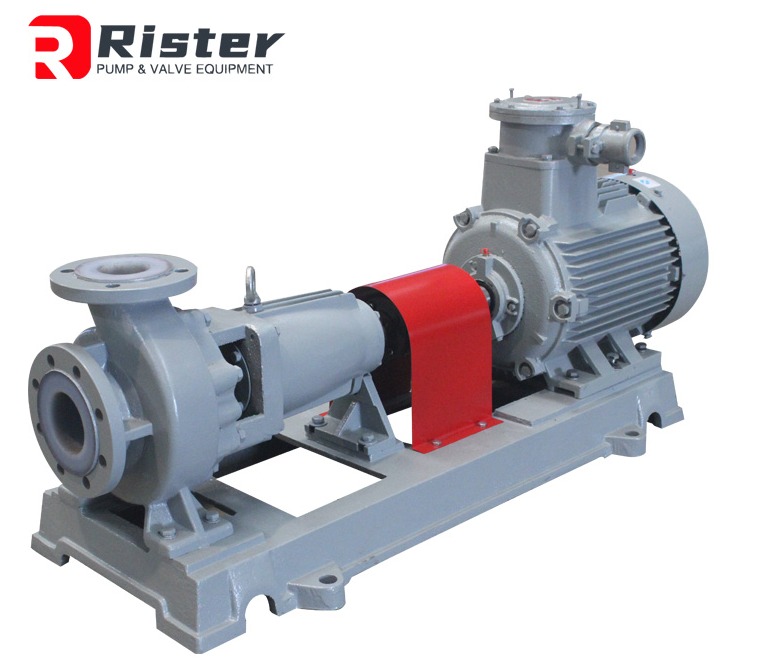

The common lining pump for the IHF series of corrosion resistant chemical centrifugal pump itself is suitable for negative 20℃~120℃ temperature conditions, can be a variety of concentrations of acid, alkali, oxidizing media transport, impeller and pump cover with metal insert external fluorine plastic, the pump body with metal shell lined with fluorine plastic, can withstand the weight of the pipeline while withstand mechanical impact. The shaft seal adopts external bellows mechanical seal, the static ring uses 99% alumina ceramic, and the moving ring is tetrafluoroidal filling material, which is characterized by good corrosion resistance and sealing, and does not need to disassemble the import and export pipes when the parts are replaced.

IHF centrifugal chemical pump, the pump head is made of fluorine plastic lining die, the main material is polymer material, F26 material, F46 material, fluorine plastic alloy material. Due to different materials, the price error is relatively large.