Selection of concentrated sulfuric acid pump

Selection of concentrated sulfuric acid pump

The selection of concentrated sulfuric acid pump is a common problem in chemical industry practitioners, and concentrated sulfuric acid pump is used in many production processes, which inevitably involves the problem of type selection, such as improper selection, light ones can cause higher costs, more maintenance work, affect production, and heavy ones may lead to personal and property safety, so how to select the type correctly has become one of the important issues.

Case medium: 98% concentrated sulfuric acid.

Medium specific gravity: 1.84.

Medium temperature: room temperature.

Content of solid particles in the medium: 1% fine particles.

Transport flow design: 12 m3/H

Conveying head design: summary of 20 M selection:

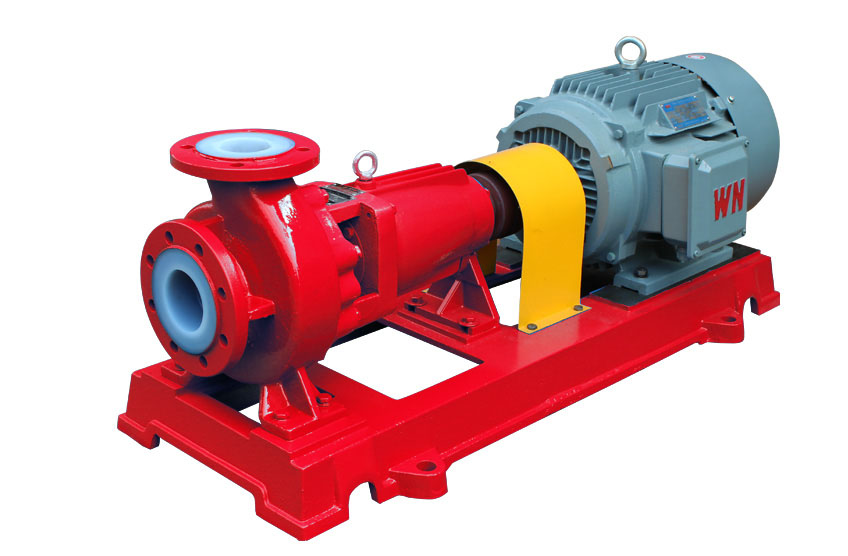

1.Material: there are many materials that can withstand concentrated sulfuric acid, but the material I suggest is still fluoroplastic (polytetrafluoroethylene / F46), because this material not only has excellent corrosion resistance, but also its sealing and mechanical strength are also prominent. in order to ensure the safety and durability in the process of conveying concentrated sulfuric acid, fluoroplastic is determined as the material of concentrated sulfuric acid pump.

2.Pump type: conveying high specific gravity concentrated sulfuric acid with a specific gravity of 1.84, it is obvious that the magnetic drive pump is not the best choice, because the magnetic torque in the magnetic pump does not meet the requirements, it is likely to lead to adverse phenomena such as "demagnetization" or "heating" (unless the magnetic coupling is selected as a "rare earth magnetic cylinder" with high magnetic performance, but this increases the cost of the pump). Therefore, I suggest using centrifugal pump.

3.The problem of motor power: because the specific gravity of concentrated sulfuric acid is 1.84, we can calculate the actual shaft power of the pump according to a simple formula, and the actual shaft power = (water test) shaft power × specific gravity.

Therefore, it can be calculated that the motor power required for the pump is at least "1.9x1.84mm 3.496", so the motor power should be selected as: 4KW.

4.Machine seal selection: the original machine seal can be ignored, but it is mentioned in the case that there are 1% fine particles in the medium, so the machine seal had better choose the wear-resistant machine seal-cemented carbide machine seal, particle-resistant machine seal.

Prev: What transparent of TPU influence for the color appearance of TPU products ?

Next: The difference between magnetic pump and shielded pump